|

Updated 8/6/2012

WindFuels Overview

While almost no one noticed,

the economics for producing clean fuels and hydrocarbons

from

water, waste CO2, and wind energy improved

by a factor of ten between 2002 and 2008. Over the past

five years, we have

applied for patents on the scientific

and technological basis for another factor-of-two

improvement in the economics. We have shown that it will

be possible (as soon

as the plants can be built) to profitably produce high-purity

carbon-neutral

gasoline, jet fuel, alcohols, and

many other hydrocarbons in volumes that cannot be matched

by any other renewable avenue, from off-peak wind energy,

waste CO2,

and water.

Our breakthroughs permit production

of gasoline, diesel, and other fuels and chemicals from

waste CO2 and

water on wind farms at twice the efficiency that was

thought likely just three years ago.

WindFuels

Concept

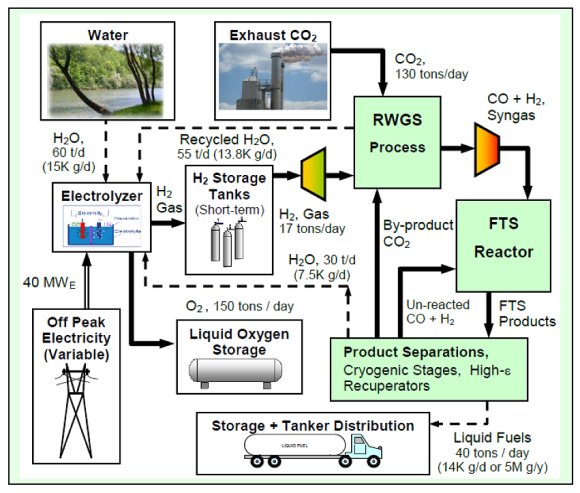

• First,

water and renewable electrical power are fed into an electrolyzer,

which produces the hydrogen needed.

• Then

waste CO2 (from

coal power plants) and the renewable hydrogen are

piped into our novel Renewable Fischer-Tropsch Synthesis

(RFTS)

plant. There, they are converted into fuels and chemicals (including

gasoline, jet fuel, and diesel).

•

These fuels may then be readily stored and distributed by conventional

means – pipelines and tanker trucks.

• The electrolyzer also produces a huge amount of oxygen, which may

be sold if market conditions warrant, or it may be utilized

in novel processes to improve the efficiency of the RFTS plant.

• There has been steady progress in the development of Gas-to-Liquids

(GTL) processes for production of fuels and chemicals of

all types over the past

30

years.

Within

the

past 5 years, many of the needed advances have been demonstrated.

• We have pending patents and proprietary technology advancing the remaining

key technical pieces. Our RFTS process is compatible with variable renewable

energy

sources, particularly wind energy, for producing alcohols and hydrocarbons

from waste CO2 and water at

maximum practical efficiency.

• We show that WindFuels has numerous economical and environmental

advantages compared to all other renewable fuels that have

been proposed.

Wind energy is by far our

most competitive renewable energy resource. There is enough wind

energy (in class 4 sites and higher, mean wind speed above 16

mph) to

supply ten times the world’s current total electrical energy

usage. The perceived challenge is getting wind energy from good

sites to where and when it is needed, both for the transportation

sector and for the power grid. Efficient conversion of off-peak

wind energy into ultra-clean, stable, liquid fuels solves both

the energy storage problem

and the grid stability problem. In doing so, it allows wind energy

to continue to grow rapidly at least through the middle of this

century.

A Major Cut In CO2 emissions.

Many have said increased fuel efficiency

in the transportation sector is the greatest opportunity for reducing CO2 emissions.

However, even a very aggressive plan to that effect would reduce global CO2 emissions

by under 5% compared to expected market forces over the next three decades – partly

because cars have an average lifetime of over 17 years and because market forces

alone will lead to improved fuel mileages at about the maximum practical rate

of a few percent per year.

The only possibly viable option that has been on the table for dealing with

climate change is CO2 separation (capture) and sequestration (CCS).

Real-world experience over the past five years at several different sites suggests

the

cost for the

sequestration

alone – not including the cost of CO2 separation from the

exhaust of coal plants – will be at least $30/ton of CO2.

(A new DOE 1-million-ton sequestration demonstration project will cost $300/ton.)

There is also still

uncertainty about long-term stability and safety of CO2 sequestration

on the scale of 10,000 times the current experimental level. Several studies

have shown CCS is likely to stimulate earthquakes, and that much of the CO2

would leak out much faster than most have thought. In about 3 decades, WindFuels

will eliminate the need for CO2 sequestration by recycling

the CO2 from

power plants (we do agree that sequestration should be implemented at new

coal plants in the meantime).

Some might argue that WindFuels are not ideal because they don’t immediately

eliminate fossil CO2, but economic realities are also essential.

When WindFuels are burned, fossil CO2 is released at that point

into the atmosphere (assuming it was made using CO2 from fossil-fueled

power plants), but it has displaced the use of oil. We can use the CO2 from

coal plants as a tool to eliminate our use of petroleum and natural gas (which

together account for over 60% of

our CO2 emissions) on a timescale that cannot be matched by any

other option. At the same time, we will prevent coal-to-liquids from competing.

• WindFuels

eliminates the need for expensive CO2 sequestration

by recycling the CO2 from power plants.

• WindFuels will be cheaper than heavy-oil products or cellulosic

ethanol.

• WindFuels could be a one-trillion-dollar market in 18 years.

•

WindFuels is the “greenest” transportation fuel

solution yet proposed: Converting CO2 into

gasoline, ethanol, diesel, jet fuel, and plastics – by

the gigaton.

•

WindFuels will be competitive with petroleum within six years,

and WindFuels are scaleable globally in less than four

decades to the 10 TW level because they are 80% based on systems

currently

in commercial production at the multi-billion-dollar

level. Each terawatt of renewable power used in the advanced

RFTS process will

produce 4B bbl/yr of fuels and other high-value chemicals – which

would likely be worth over 1.5 trillion dollars per year

in less than 20 years.

|

|

| |

|

| |

| For those that are not scientists,

or engineers or are not very familiar with

chemical engineering, we have a WindFuels

Primer to

help you get started. |

| |

How are WindFuels carbon neutral?

No new fossil carbon is required. WindFuels

use wind energy, waste CO2 (from coal power

plants), and water to make clean alcohols and other fuels. |

| |

| An average

acre of land in the Dakotas, Kansas, or Wyoming will produce

4 to 15 times as much

fuel from wind, water, and waste CO2 as an

average acre of land in fertile farming areas devoted to

biofuels – and

do it much more cost effectively and with less societal and

environmental impact |

| |

What is FTS?

Fischer-Tropsch Synthesis is a controlled chemical reaction involving carbon

monoxide (CO) and hydrogen (H2). The CO and H2 pass

through a catalyst at high temperature and pressure, which causes the gasses

to combine

to form

various

hydrocarbons. If you run

across the acronym “RFTS”, that’s merely an FTS process that

is fueled through renewable sources – so it’s a Renewable FTS process. |

| |

| The scalability

of liquid WindFuels over the next four decades exceeds that

of cellulosic ethanol by at least a

factor of 5, and there are no major adverse environmental

concerns. |

| |

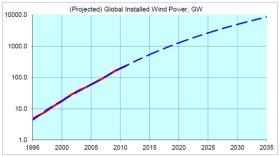

| The

global growth rate in wind energy has averaged 22% for

the past 17 years. Converting the off-peak wind energy

(beyond that needed for the grid) to liquid fuels will

allow this

growth rate to continue unabated for another 20 years. |

| |

Installed global (peak) wind energy

projection based on a fourth-order fit to the data from the

past 17

years. |

| |

| $$$ CO2 sequestration will be at least $30/ton. (A new

DOE million ton sequestration demonstration project will

cost $300/ton.) $$$ |

| |

|

|