|

The

WindFuels™ Primer

- Basic Explanation

for the Non-scientist

The

WindFuels™ Basic Process Explanations.

WindFuels™. Now that is a word you have not heard before.

So what are WindFuels™? The concept is really not complicated.

We will use energy generated by wind to power processes that will

recycle waste

carbon dioxide into transportation fuels for automobiles, like

diesel, ethanol or gasoline. We can also make fuels like jet fuel

and

propane.

(We are talking mostly about fuels, but the FTS process can also

produce

ethylene and propylene which are used to

make plastics – used in everything from textiles to

tables.)

We'll recycle CO2 from

power plants or other exhausts (which release CO2into

the air, contributing

to global warming). Because we have removed the CO2 from

the air to make the fuels, using (burning) WindFuels releases no

new carbon, making it a carbon

neutral process. Replacing oil with WindFuels will reduce total

CO2 emissions

by 40%.

No experienced chemist has doubted that it is possible to convert

CO2 to fuels. The problem has

been that prior proposals for doing this conversion have had

efficiencies of only 20% to 30%.

The combination of the eight

major technical advances we have made over the past five years

will now permit this conversion

to be done at 60% efficiency. That’s high enough for carbon-neutral

fuels made from waste CO2 to easily

compete with petroleum on a cost basis, especially when the input

energy is from excess wind energy in the middle of the night.

What we are doing is not magic. It is just good chemistry, physics,

and engineering. Because we are using the carbon from waste CO2 rather

than coal, we have to add a lot of energy from wind. However, when

all the processes are properly optimized, the cost of this energy

becomes affordable. It is a small price to pay to dramatically

reduce greenhouse gases in the atmosphere and provide a limitless

supply of clean transportation fuels.

Fuels like ethanol, gasoline and jet fuel are hydrocarbon fuels.

Hydrocarbons and alcohols are chemicals that contain hydrogen (H),

carbon (C) and oxygen (O). We will use water (H2O)

and the waste (polluting) carbon dioxide (CO2)

from power-plant smokestacks to provide the carbon, oxygen, and

hydrogen needed to make fuels like ethanol (C2H5OH)

and gasoline (C8H18).

Here's How: (Later

on this page, we’ll explain each of these processes -

and we will try to explain them in a clear way.)

Wind

Farms

|

1. Wind Farms generate

electricity for electrolysis and other processes. |

|

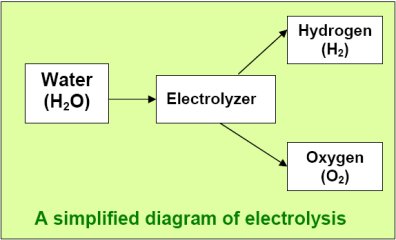

2. Electrolysis is the process in which electric current

is passed through water (H2O) to break the bonds

between the hydrogen and the oxygen, yielding hydrogen (H2) and Oxygen

(O2). |

RWGS & FTS Plant

|

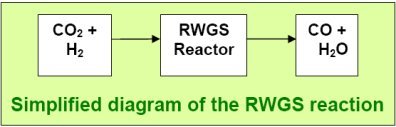

3. Reverse Water

Gas Shift (RWGS) is used to

produce carbon monoxide (CO) from carbon dioxide (CO2). |

| 4. In a widely used process

called Fischer

Tropsch Synthesis (FTS),

the liquid fuel production from hydrogen (H) and carbon

monoxide (CO) occurs. |

WindFuels™

|

5. The resulting products will

fuel our cars, trucks or

jet planes and are:

Carbon neutral

(WindFuels do not release new CO2 into

the air. The carbon was recycled from exhausts.)

Renewable (Both wind and CO2 are

replaced. In contrast – oil and coal which are

used up are not renewable.)

Economical (competes on a price basis)

Contributing to Energy Independence!

|

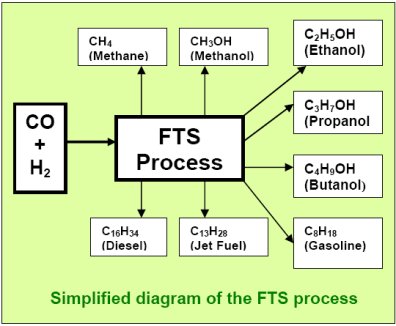

Overview of FTS (Fischer

Tropsch Synthesis)

The liquid fuel production from hydrogen, carbon, and

oxygen occurs in the Fischer Tropsch (FT) reactor. FTS has been

used in commercial

production

of liquid

fuels of

all types from coal or natural gas (gas) for over 60 years.

FTS was used in Germany during WWII to generate

fuels when crude oil was scarce, so the process is not

new.

The process has not been used much in

the United States because oil was cheap and plentiful. Utilization

of the FTS processes has been increasing, as coal and

gas are now much cheaper than oil. (If we use waste CO2 in

place of gas or coal in FTS, we can supply fuel and reduce

the CO2

in the air.)

The FTS process uses catalysts to efficiently convert a feed

mixture of carbon monoxide (CO) and hydrogen (H2)

to hydrocarbons of all

types. Different catalysts and different operating conditions

can help “select” for higher yields of some hydrocarbons

than others, but there will always be a mixture of different

products created by the reaction:

In conventional FTS, the syngas is obtained from high-temperature

reforming of coal or methane. Usually, the FT catalysts and conditions

(pressure, temperature, and mixture) have been chosen to obtain mostly

gasoline, diesel, and waxes from the FT reactor. Recent progress

in the catalysts and conditions now allow high yields of ethanol,

propanol, and butanol also.

Getting clean hydrogen - Electrolysis

Electrolysis is used rather than fossil fuels to generate the hydrogen

for our WindFuels. Electrolysis is the process in which electric current

is passed through water (H2O) to break the

bonds between the hydrogen and the oxygen, yielding hydrogen (H2)

and Oxygen (O2).

Electrolyzers

for efficiently splitting water into high purity hydrogen and

oxygen have been in industrial production for decades. A solution

of potassium hydroxide (KOH) in water is used because it has

low

resistivity and thus lower power loss. The addition of electrons

at the negative electrode (also called the cathode) produces

hydrogen gas (H2) and hydroxyl

ions (OH-), which remain in the solution. At the positive electrode

(also

called the anode), electrons are removed

from OH- ions, producing water (H2O)

and oxygen (O2). A membrane that

is permeable to the OH- ions (and possibly to water too)

separates the two electrodes to keep the gases from mixing

while allowing the

electrical current to flow through it on the charge carriers.

In practice, the solutions on both sides are continually flowing

to

maintain the desired salt concentrations. The two gases produced

also contain a lot of water vapor (which is easily separated)

but only minute traces (easily under 0.1%, and sometimes

under 0.01%) of

other impurities (primarily the other major gas, either O2

or H2).

Efficiency of commercially available 2 MW (megawatt) electrolyzers

has typically been 73%. Laboratory experiments have exceeded

85%

at higher

pressures and lower current densities, and we have shown that

the waste heat

(at 160 0C) can be utilized at

30% efficiency. Total system efficiency of a 250 MW electrolysis

system may eventually approach

90%.

A quick note about water, the FTS process will require about

5 gallons of water for every 3-4 gallons of produced fuels, which

is at least

an order of magnitude less than the water requirements for

biofuels. Using reverse-osmosis, water sources as impure as seawater

can be

used, which would add only $0.01/gallon to the cost of the

fuel produced. Water will not be a limitation.

Getting

the CO: The Reverse Water Gas Shift (RWGS)

The next step is to efficiently get the carbon monoxide

(CO) needed in the syngas from CO2.

There is a very robust and efficient reaction that has been known

for the past century as the water gas shift reaction (WGS). This

is used in fossil-fuels FTS to generate hydrogen by combining

CO (from fossil fuels) with steam at high temperatures (400-800

0C)

to form hydrogen and carbon dioxide.

The fossil fuels FTS

systems have no trouble getting carbon monoxide, and use excess

carbon monoxide to get the hydrogen they need for proper syngas

mixtures. The reverse is true for clean, renewable WindFuels. Through electrolysis,

we can efficiently

get all the H2 we need, but we

need an efficient way of getting the CO.

The reverse of WGS reaction, known as the reverse water gas

shift (RWGS) provides a robust method of producing CO

and water from CO2 and H2.

Getting this reaction to achieve high yield of CO at high efficiency

with low production of unwanted methane (CH4)

has previously been a challenge, but we have shown elsewhere

in detail

how this can now

be achieved achieved at very high efficiency.

The syngas (remember, the CO plus H2 mixture)

then goes to the FT reactor, where it is adsorbed onto the surface

of the catalysts

(often

small metal particles), where it is reformed into hydrocarbons

(such as gasoline, propane, and diesel), alcohols (including

ethanol and

propanol), water, and waste heat. As these reactions are

exothermic (heat is released), they proceed readily. The reaction

efficiencies

here are in the range of 70-85%, depending on the compound

that is formed, with the higher efficiencies being for the light

alcohols

(methanol and ethanol). We have shown elsewhere in detail

how the waste

heat from the reactor can be utilized at over 40% efficiency.

The output from the FT reactor includes the desired products

(alcohols, jet fuel, propane, etc.) along with a lot of

unreacted inputs

(CO and H2) and some undesired

products – water, CO2,

and methane. One of the most important keys to achieving

high system

efficiency

is devising extremely efficient methods of separating and

recycling the unwanted components. We have developed important

improvements in separations and recycling. Elsewhere

we have shown how this can be done.

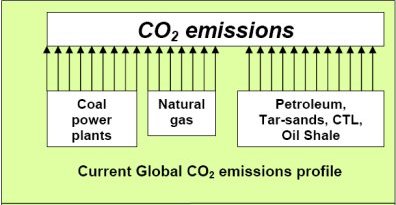

Fossil-Based

FTS is dirty. Windfuels are a path to true Global Warming

Mitigation.

The biggest problem with fossil-based FTS is that an enormous amount of polluting

CO2 is released – especially if coal is

used. For every kg of coal used for coal-to-liquids (CTL) diesel, 2.2 kg

of CO2 are emitted and 0.3 kg of fuel is produced.

(Even NG-based FTS results in about 25% more CO2 total

release than simply using conventional oil.) WindFuels uses similar FTS processes,

but begins with carbon-neutral “syngas” (the feed mixture of

CO and H2) made from water (H2O)

and waste CO2 (from coal plants). This can be

done at very high efficiency with zero net carbon release, as we show in

detail elsewhere on this website and summarize below.

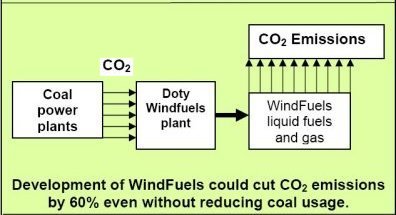

| Below: Since

the CO2 was removed from the air (or smokestacks)

to make the WindFuels, no new CO2 has been

released. The carbon was recycled. The net carbon from

WindFuels is zero. |

Some may say that the CO2 from

coal is eventually released, and this is therefore not carbon

neutral. However, many of those same people have probably either

bought carbon offsets or at least looked into the idea. The

principle of carbon offsets is to reduce carbon emissions elsewhere

to offset the carbon you are generating. Well, the coal from

the coal power plants (which provides electricity to hundreds

of millions of homes) emits billions of tons of CO2.

If we recycle that CO2 to produce

WindFuels, it will still eventually be emitted, but oil and

natural gas – as well as much more environmentally destructive

fuels such as coal-to-methanol, tar-sands fuels, and oil-shale

fuels – are NOT burned and are therefore NOT emitting

CO2… which reduces overall

greenhouse gas emissions.

Eventually, the CO2 can be taken from the atmosphere

rather than from smokestacks, but that will be more expensive. Today, using

CO2 from the atmosphere might make the WindFuels

40% more expensive. Thirty years from now, we’ll probably be able to

do it for just an 8% cost penalty. We can’t wait 30 years to get started.

We'll start with CO2 from smokestacks.

Perfectly Solving the Grid

Stability Challenge.

We’ve all probably heard it will not be possible to stabilize the power

grid if much more wind energy is added, and the result would be frequent regional

grid failures and blackouts. Without a solution to the energy storage problem,

that would be true. The electric grid stability challenge arises from changes

in grid supply (power plants, wind, and solar) not being able to follow the changes

in grid demand (from users) quickly enough. Wind power is often greater in the

middle of the night when demand is minimal. “Clean coal”, nuclear,

and many of the older natural gas power plants take many hours to turn down,

and there is not a cost effective method of storing energy other than pumped

hydro storage, which is not an option in most areas. (Compressed air energy storage,

CAES, will be either very expensive or quite inefficient.)

WindFuels will only draw

power during off-peak hours when there is excess renewable

energy available at very low cost. Off-peak power rates are often

under

15% of peak rates to encourage more use of it. The WindFuels electrolyzer can

respond within milliseconds to changes in supply and demand. It will completely

solve the grid stability problem by storing the excess peak grid energy temporarily

in compressed hydrogen and then converting it to liquid fuels (which are easily

stored and distributed) at a fairly steady rate around the clock. Storing enormous

amounts of energy in hydrogen is considerably more expensive than storing energy

in liquid fuels, but storing enough hydrogen to keep the FTS

plant

going steadily around

the clock (to efficiently convert the hydrogen to liquid fuels) will not be

either too expensive or too risky.

Improving

the competitiveness of fuels from CO2.

The Windfuels process seems unquestionable destined to

be the dominant, sustainable solution for transportation fuels

in the future, but electrolyzers today are

still expensive. Hence, the capital outlay for the electrolyzers (for perhaps

the next five years) may be beyond what most investors wish to consider in today’s

risk-averse world.

That has motivated us to begin developing a less expensive “bridging” approach

to synthesizing fuels from a combination of CO2,

methane (from shale gas), water, and renewable energy. The outcome of this research

is a process we have dubbed

CARMA-GTL, for Carbon dioxide Advanced Reforming of Methane Adiabatically, with

GTL. As explained in a paper recently presented at the national ACS meeting,

as long as low-cost natural gas is available, our CARMA-GTL process reduces the

electrolyzer requirements by a factor of three to ten while actually increasing

plant efficiency. Since most of the carbon in these fuels comes from shale gas

(only a minor fraction comes from CO2), these fuels

are only slightly carbon neutral (like most biofuels). However, the CARMA-GTL

plants will be much less

expensive than Windfuels plants, and they will be able to steadily transition

to using more renewable energy and less shale gas. Developing this technology

will begin to drive the cost of electrolyzers down and allow investors to become

more comfortable with coming Windfuels paradigm.

|

|

Western

Research Institute's

Test Fischer Tropsch System

|

| Better

than sequestration?

Sequestering a ton of CO2 prevents

one ton of CO2 from being emitted into the

atmosphere, adding a significant cost burden.

Pumping one ton of CO2 into

a WindFuels plant would profitably create about 170 gallons

of liquid fuels (~0.56 tons), which keeps additional

fossil fuels from being consumed .

Since

the CO2 is removed from the air (or smokestacks)

to make the WindFuels, no new CO2 has

been released. The net carbon from WindFuels is essentially

zero.

Net CO2

added to the atmosphere

for 1 ton of various liquid fuels:

|

FUEL

|

CO2

|

| WindFuels |

0.2 tons

|

| Ethanol from established corn fields |

2.9 tons

|

| Conventional Oil |

4.4 tons

|

| Deep Sea Oil |

5.3 tons

|

| Heavy Oil |

5.7 tons

|

| Oil Shale, ICP |

6.0 tons

|

| Tar Sands |

6.0 tons

|

| Oil Shale, ATP |

6.5 tons

|

| Coal-to-liquids |

10 tons

|

Shockingly,

newly plowed grasslands converted to crops

releases tons of CO2.

(see Science 319, 1235-1238,

Mar 21, 2008.)

|

| |

| We

are using wind energy because it is the most cost effective

renewable power source in the United States. In some countries,

another renewable energy source like solar or geo-thermal

would be more appropriate. |

|

|

|

|